DeMAG™ Benefits

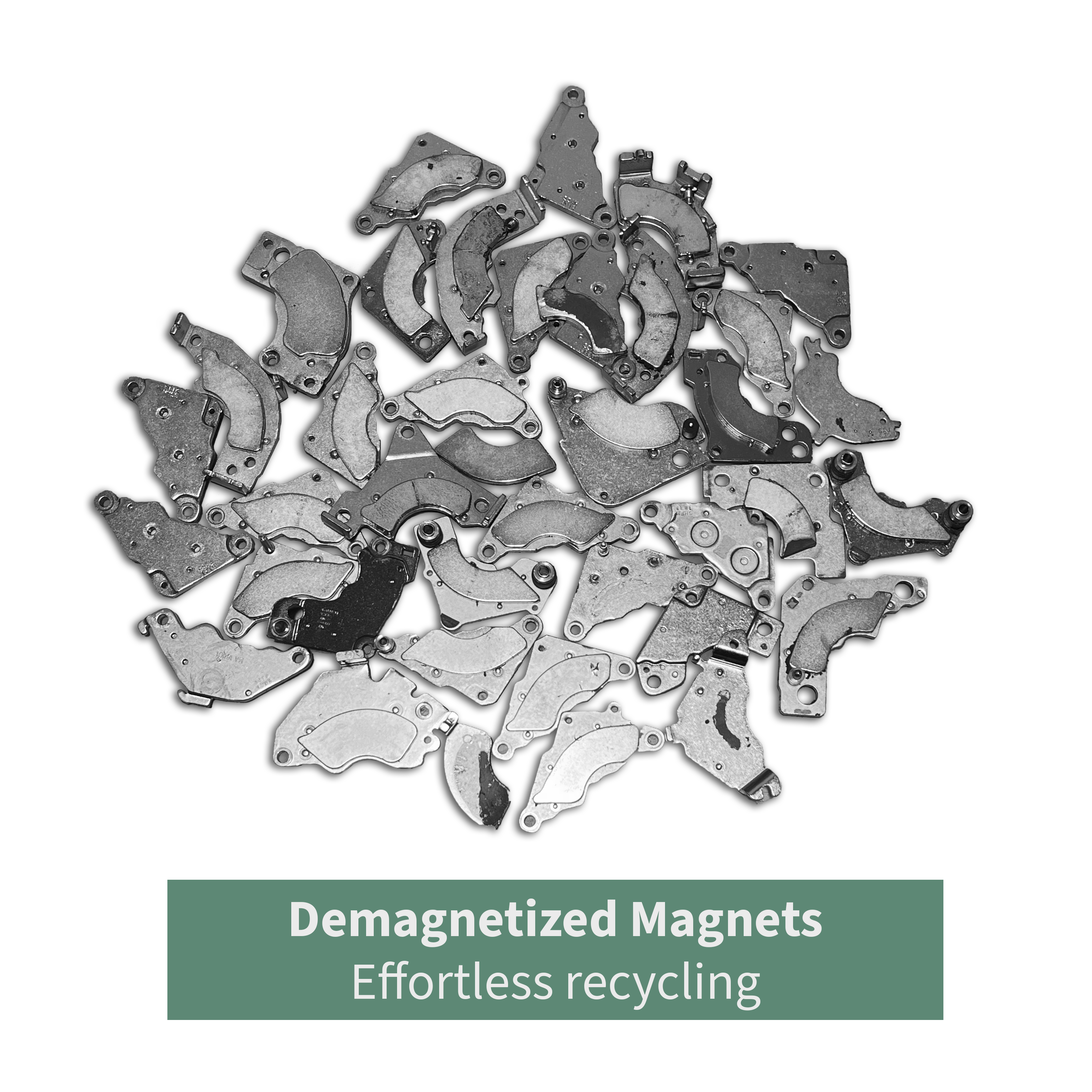

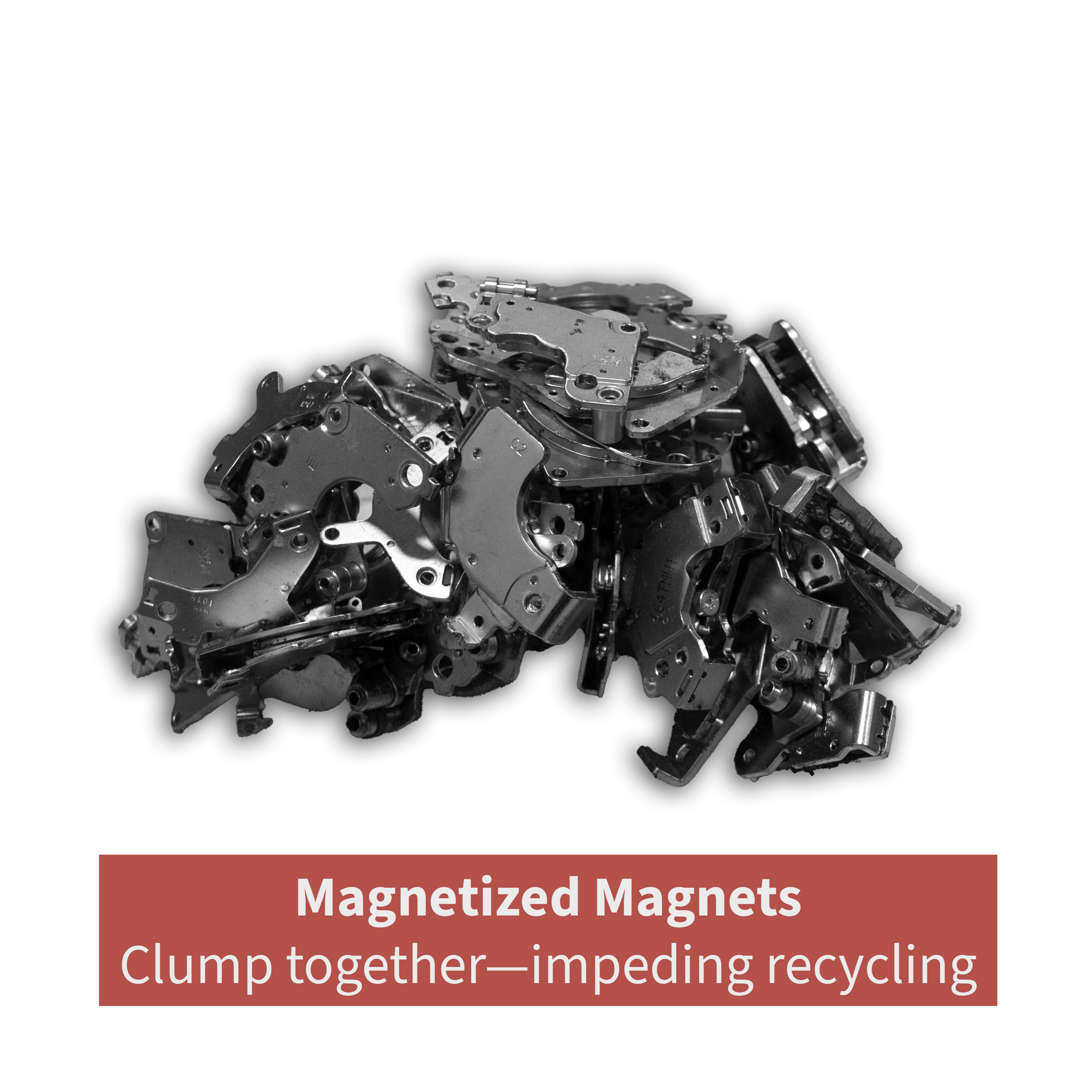

- Pioneering Environmental Sustainability: The DeMAG™ demagnetizes the powerful neodymium magnets, preventing the magnets from attaching together, making them easy to manage and sort after disassembly for recycling.

- Unparalleled Data Security with IRONCLAD Verification: When equipped with Garner’s exclusive IRONCLAD verification system, the DeMAG™ ensures verifiable data destruction.

- Revolutionary HDD Decommissioning: Pairing the DeMAG™ with Garner’s DiskMantler™ creates a groundbreaking solution for HDD decommissioning, ensuring verifiable data destruction, efficient hard drive disassembly, and high-value component recycling.

- Eco-Friendly Innovation: Specifically designed for HDD decommissioning, the DeMAG™ is ideal for data centers and recycling facilities. Its ability to sanitize HDDs of all data and demagnetize the rare-earth magnets, combined with seamless integration with Garner's DiskMantler™, offers the most comprehensive solution in sustainable HDD recycling.

- Scalability: The DeMAG™ is designed to accommodate automated systems like conveyor belts, robotics, and stackers for scalable decommissioning process.

DeMAG™ Features

- Advanced Multi-Pulse Super Degausser: The DeMAG™—a patent-pending super degausser—delivers multiple pulses of gauss, peaking at an immense 40,000 gauss, thoroughly destroying all traces of data on hard drives, providing unparalleled data security.

- Automatic Operation: Insert the HDD into the media slot, and in approximately 1 minute, the DeMAG™ automatically delivers enough gauss to degauss and demagnetize the HDD for efficient and secure processing.

- IRONCLAD Erasure Verification: When equipped with Garner’s exclusive IRONCLAD system, the DeMAG™ ensures verifiable data destruction. After demagnetization, the drive is transported to the image-capturing area within the DeMAG™, where the system takes a JPG image, documents, and records the data erasure process, providing proof that the media was properly sanitized of all data. With or without IRONCLAD, operators can monitor the process through the polycarbonate top panel.

- Compact Design: With a footprint of 18.5” x 9.8” x 24.8” (HxWxD), the DeMAG™ integrates seamlessly into any existing environment.

- Effortless Maintenance: The DeMAG™ operates cleanly, producing no debris and requiring minimal upkeep for the destruction chamber. Internal components need maintenance only on rare occasions, ensuring reliable performance with little intervention.

- Continuous Operation: Engineered for efficiency, the DeMAG™ runs continuously without the need for cooldowns between cycles, maximizing throughput and uptime.

- TAA compliant: Proudly made in the U.S.A., the DeMAG™ is manufactured at Garner's California facility.

Best Practices:

As an industry best practice, when a company gathers customer data, there is a legal obligation to safeguard this data diligently, ensuring comprehensive protection from the initial point of acquisition through to the end-of-life decommissioning process. Physical destruction of hard drives alone leaves data behind (i.e. shredding, crushing, piercing, bending). Below, is a simple decommissioning process utilizing the DiskMantler™ and Garner's DeMAG™ (patent pending) that will provide secure end-of-life processing for hard drives:

- As the first operation in the hard drive decommissioning process, use Garner's exclusive DeMAG™. Generating nearly 4 Tesla, the DeMAG™ acts as a super degausser that demagnetizes the HDD disk platters of all data and demagnetizes the magnets within the drive. In addition to ensuring the data is forensically unrecoverable, the rare-earth magnets within the drive no longer adhere to one another or other objects, which results in optimal magnet handling efficiency.

- After degaussing, simply put the HDD through the media slot of the DiskMantler™. The DiskMantler™ uses shock, harmonics, and vibration to disassemble the HDD. The HDD's components are now ready to be recycled.

Note: Solid-state media cannot be degaussed.

HDD Demagnetizing while Maintaining Regulatory Compliance

In addition to the recycling benefits, the DeMAG™ will help you meet the most stringent data security standards requiring media data destruction prior to disposal, including:

- DoD below Top Secret

- CCPA (California Consumer Privacy Act)

- GDPR (General Data Protection Regulation)

- GLBA (Gramm-Leach-Bliley Act)

- HIPAA (Health Information Portability and Accountability Act)

- IRS 1075

- NIST SP 800-88r1

- PCI DSS 3.2 (Payment Card Industry Data Security Standard)

- PIPEDA (Personal Information Protection and Electronic Documents Act)

Sustainable Practices.

Eco-Friendly Products

We are proud to be an eco-friendly manufacturer in California, the state that sets the standard for environmental protection. At every stage of the manufacturing process, from product design through manufacturing and shipping, we apply processes and use materials that minimize environmental impact.

For optimal hard drive decommissioning, pair the DeMAG™ with the DiskMantler™. Through a process of shock, harmonics, and vibration, the DiskMantler™ automatically disassembles decommissioned hard drives into their major components—case, cover, PC boards, platters, voice coils, and rare-earth magnets.

In just 8 to 90 seconds per drive, this hands-free, automated process simplifies the extraction of HDD components and rare-earth elements, and their reintegration into the supply chain, significantly reducing e-waste and minimizing negative environmental impact compared to traditional shredding, crushing, or melting methods. Together, the DiskMantler™ and DeMAG™ offer the most comprehensive solution for verifiable data destruction, hard drive disposal, and recycling.

Contact us to learn more about the DeMAG™.